+86-769-38973158

+86-769-38973158 +86 13622624429

+86 13622624429 machinery_vk@21cn.com

machinery_vk@21cn.com

+86-769-38973158

+86-769-38973158 +86 13622624429

+86 13622624429 machinery_vk@21cn.com

machinery_vk@21cn.com

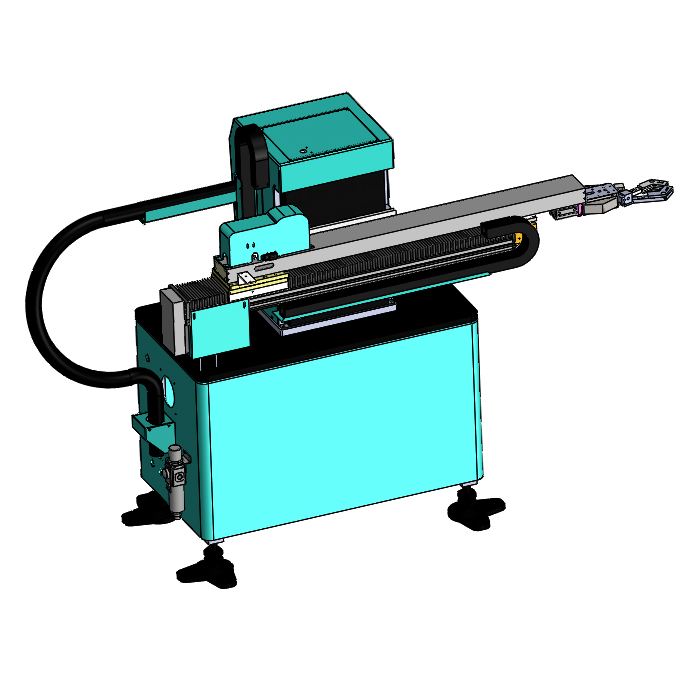

Two axis forging manipulator is an automated mechanical equipment suitable for forging production, with advantages such as high efficiency, reduced labor costs, improved product quality, and improved production environment.

A two axis forging robot generally consists of a hand, wrist, arm, column, and base. The hand is used to grasp the billet, the wrist rotates the hand in space, the arm sends the hand to the desired position, and the column and base ensure the stability of the robotic arm in space.

When choosing a two axis forging robot, factors such as the robot's stroke (the range that the hand can reach), gripping weight (the maximum weight that the hand can grip), positioning accuracy (the precision of the hand reaching the designated position), as well as the robot's ease of operation, maintenance convenience, and price need to be considered.

Two axis forging robotic arms are suitable for various forging production fields, such as automobile manufacturing, aerospace, power, shipbuilding, steel, petrochemicals, etc. In these fields, robotic arms can be widely used in the automated production of various forging equipment to achieve automated grabbing and handling of billets.

In addition, the two axis forging manipulator also has some technical characteristics, such as the universality of forging automation production, two axis high-strength mechanism, large stroke, stable servo drive performance, and improved operating accuracy. At the same time, it can also be matched with customers' existing machine tools to achieve automatic forging, and the operation is simple, the interface is friendly, and it is convenient for employees to learn.

In summary, the two axis forging manipulator is an indispensable automated mechanical equipment in forging production. Its application will greatly improve production efficiency, reduce labor costs, enhance product quality, and improve the production environment.